This technical artical will describe how a fused optical fiber coupler works and how it is made.

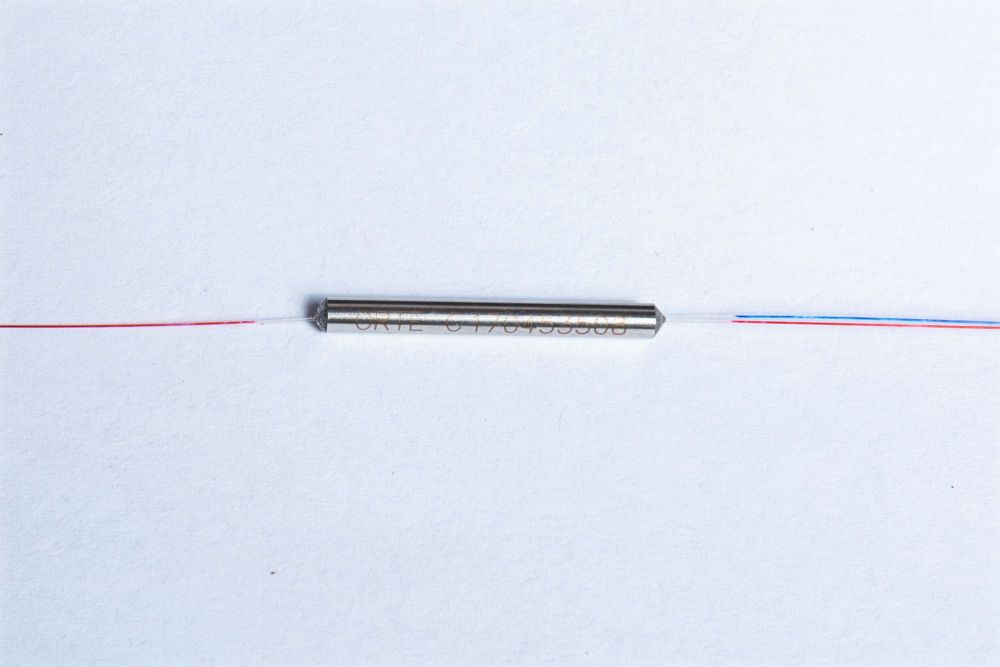

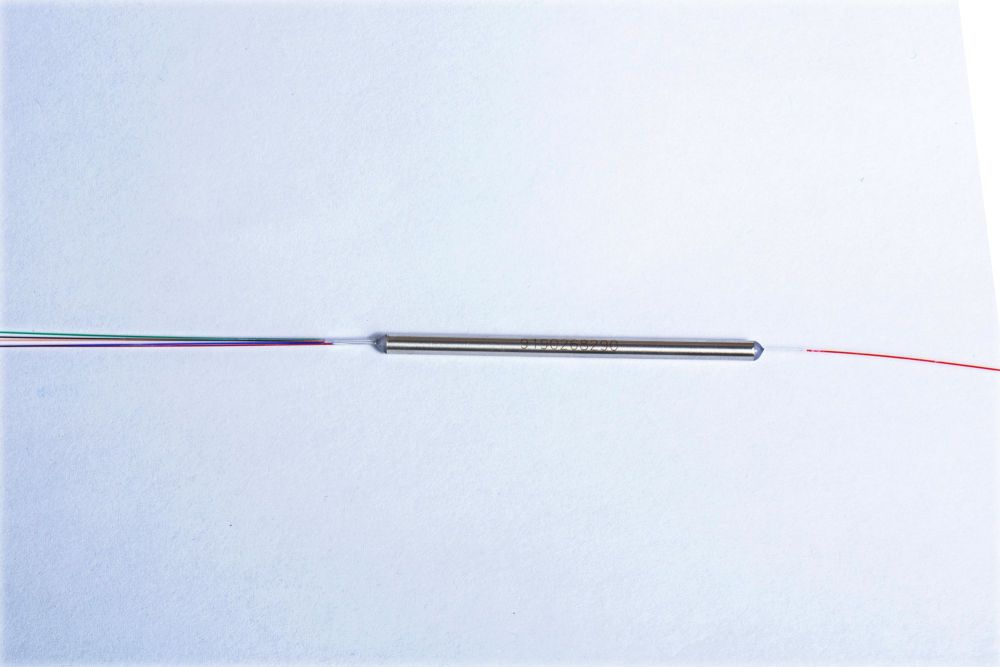

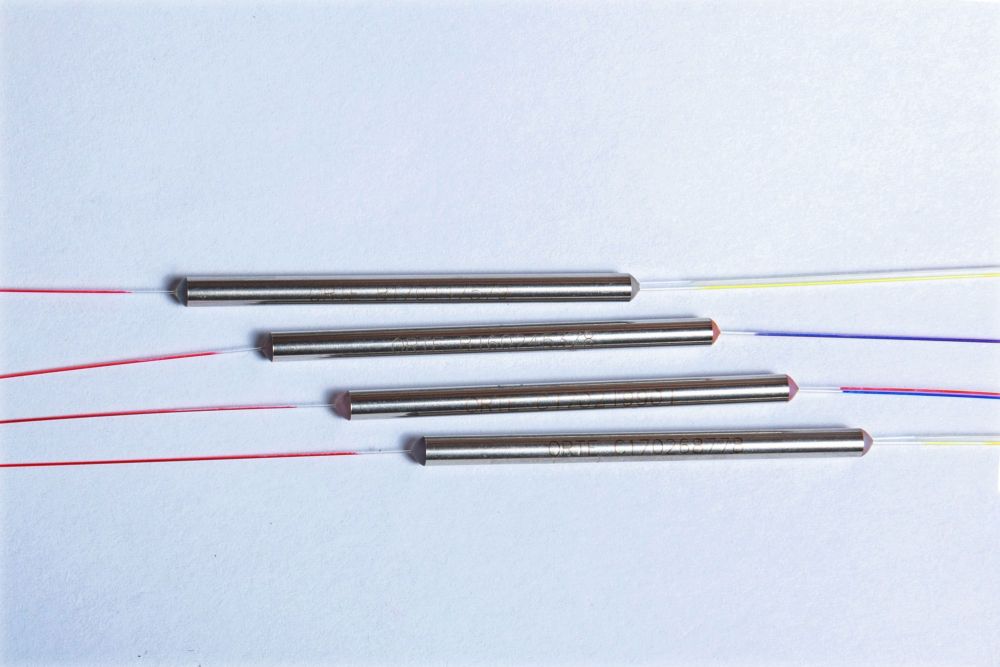

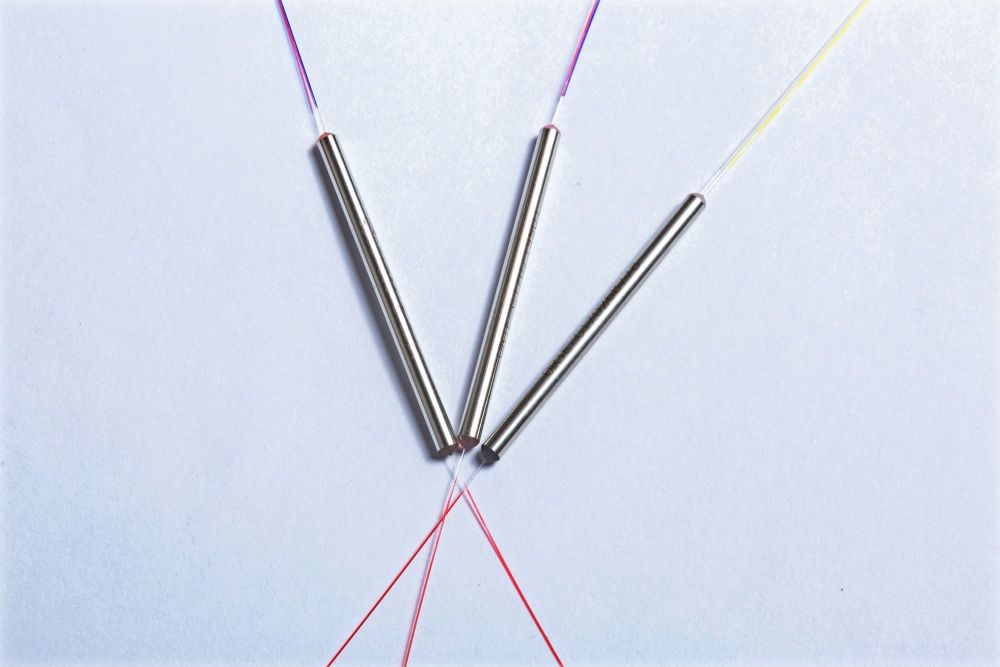

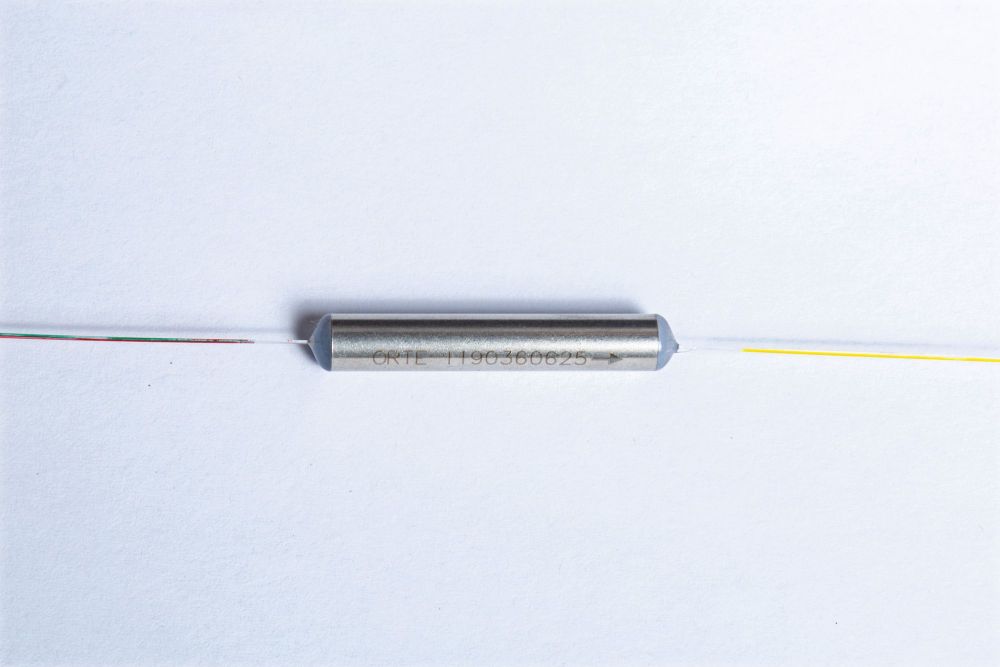

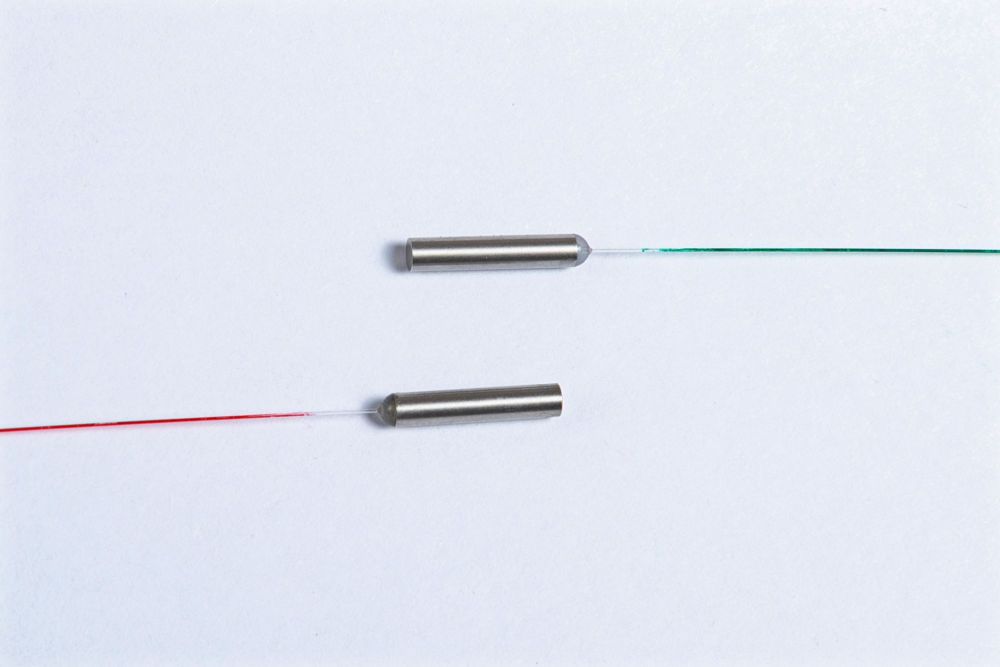

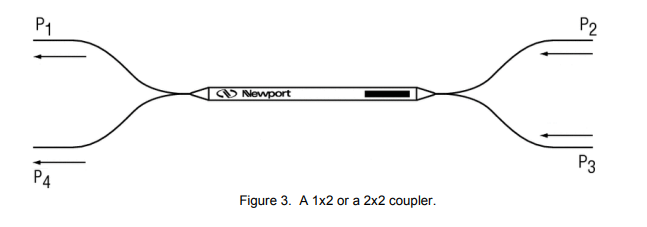

A fused coupler basically consists of two, parallel optical fibers that have been twisted, stretched and fused together so that their cores are very close to each other. This forms a Coupling Region as shown in Figure 1 below. The length of this Coupling Region, L, determines the coupling ratio from one fiber to the other. During the manufacturing process, light is launched into an input port, P, and the output power from each output port is carefully monitored. When the desired coupling ratio is achieved, the fully automated manufacturing process is stopped. The resulting coupler is essentially one fiber with two cores that are very near to one another. This process is known as the Fused Biconical Taper (FBT) process.

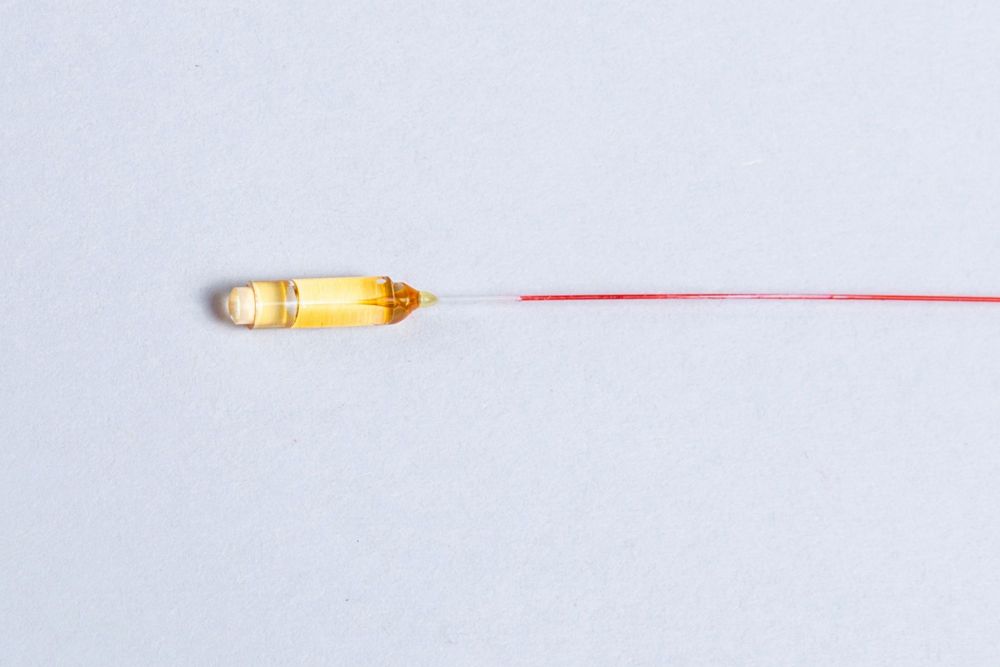

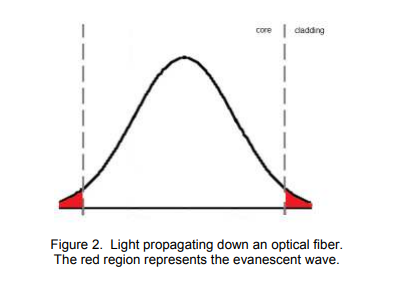

The intensity profile of light traveling down a singlemode fiber is essentially Gaussian; that is, the intensity is greatest in the center and tapers off as the core/cladding interface is approached. The tail ends of the Gaussian profile extend slightly through the core and into the cladding. This tail is called the evanescent wave. Figure 2 represents the cross section of a light wave in an optical fiber. The vertical dashed lines represent the fiber core/cladding boundary. The red tails are the evanescent wave.

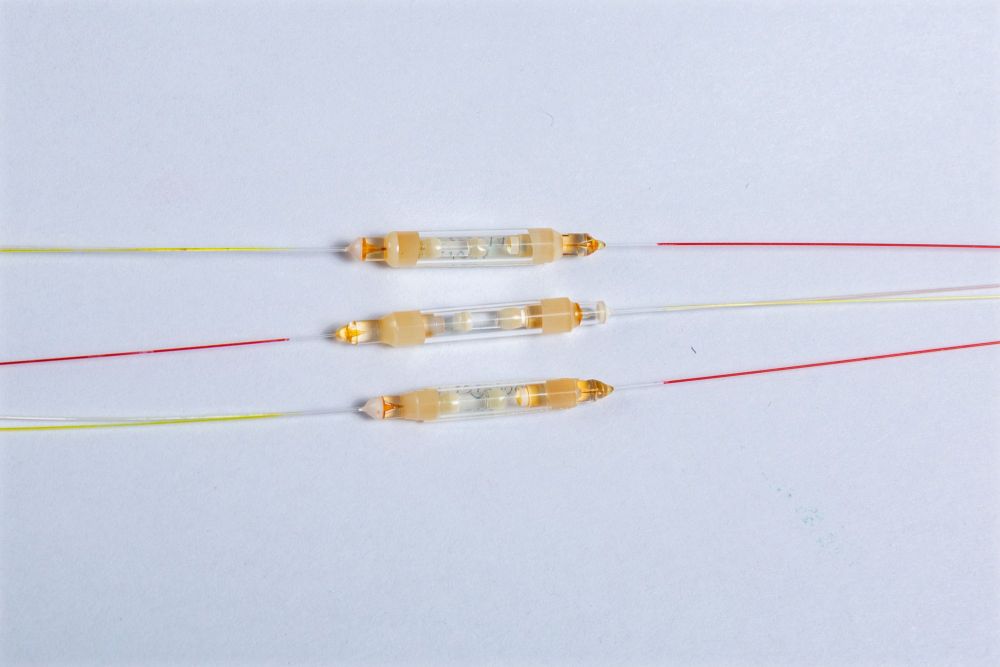

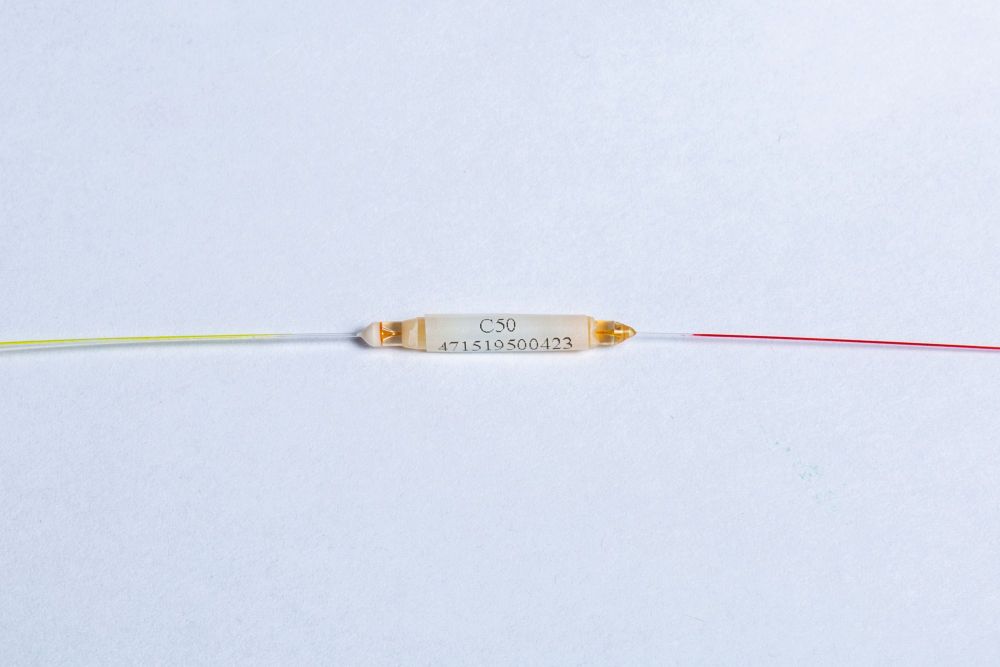

In a standard 50/50, 2x2 coupler, the idea of reversing the launch direction is immediately clear. The process is completely bi-directional. Confusion sometimes arises, however, when presented with a 1x2 coupler. The apparent non-symmetry of the device creates the false impression that the device somehow works differently. Continuing the last (1x2) example, what happens if light is launched into one of the two “output” ports; that is, ports 2 or 3? Does 100% of the light exit at port 1? Of course not. Light still “wants” to exit from port 4 as well. So if we consider 1 mW launched into port 2, we will have just 0.5 mW exiting from port 1. Or, if we launch 1 mW into port 2 and 2 mW into port 3, we will have 1.5 mW exiting from port 1. We just need to realize that a 1x2 coupler is just a 2x2 coupler with one fiber cut short, crushed (to reduce back reflection from the end facet), and tucked away inside the housing of the coupler. In this case we can see how an understanding of how a fused fiber optic coupler is made and how it works helps us to understand how this reverse process works.