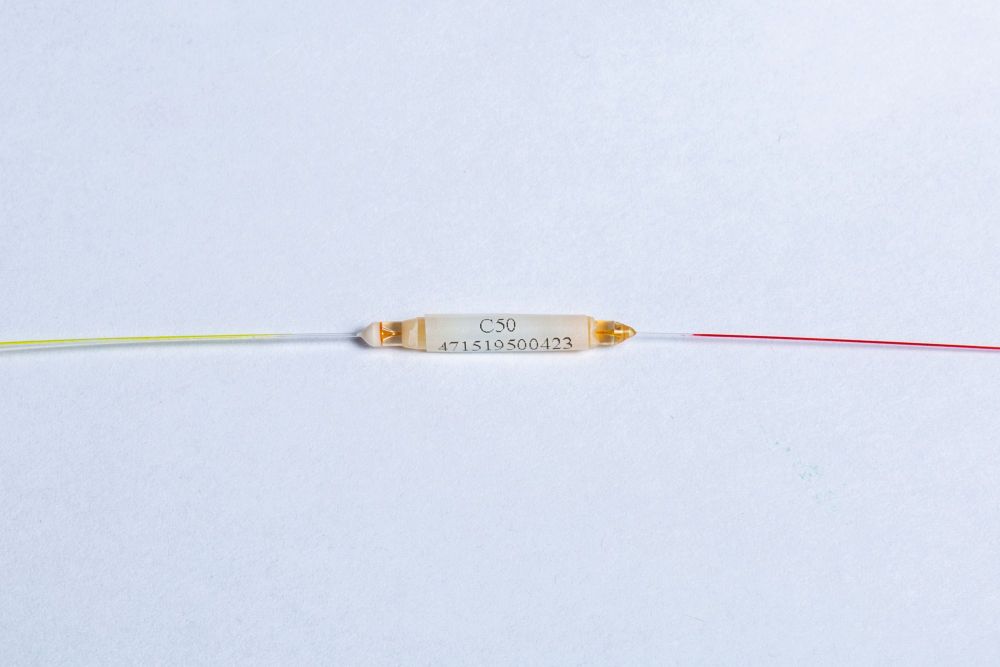

ORTE photonics prioritizes and emphasizes the quality and reliability of our products first, including FBT couplers. All of our licensed and qualified products observes GR-1221 and GR-1209. How do we promise that? We carry on our strict experiment to make sure that, which is often called Failure Modes and Effects Analysis, or FMEA.

According to our analysis, one of the most common failure modes is water corrosion to the fiber optics. Even a little water vapor allows it happen. The surface of the glass adsorbs water vapor and undergoes a slow hydrolysis reaction, resulting in the rupture of the silicon-oxygen bond in the network structure—Si—O—Si—, and the bridging oxygen becomes non-bridging oxygen. Cracks keep growing. The stress also promotes the continuation of the bond breaking reaction. Therefore, the growth and expansion rate of the fiber break is the result of the combined action of stress and water corrosion.

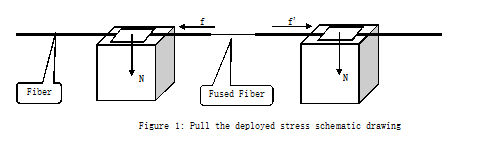

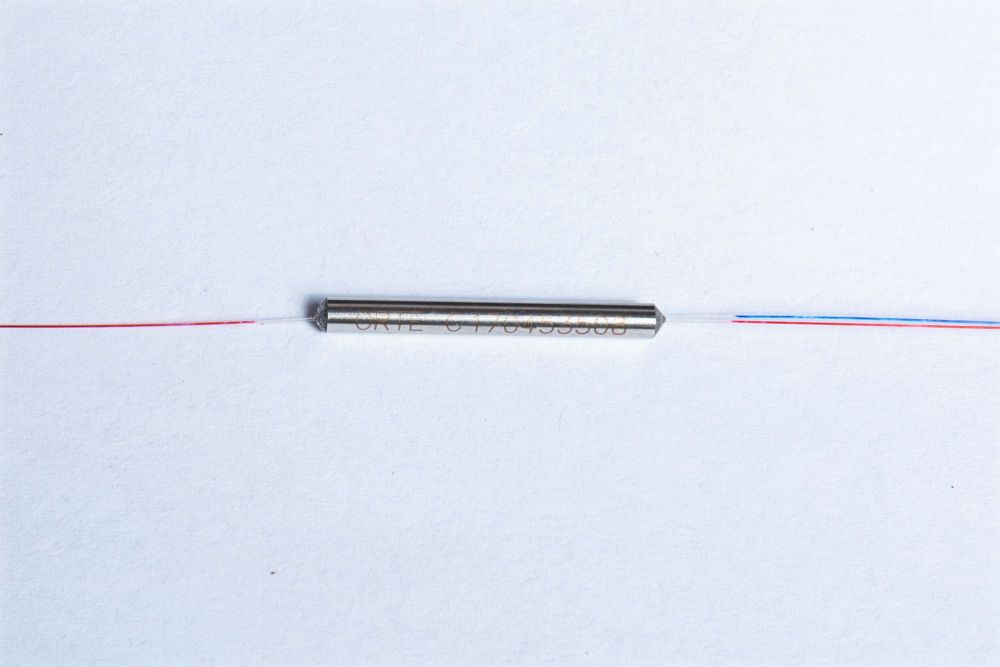

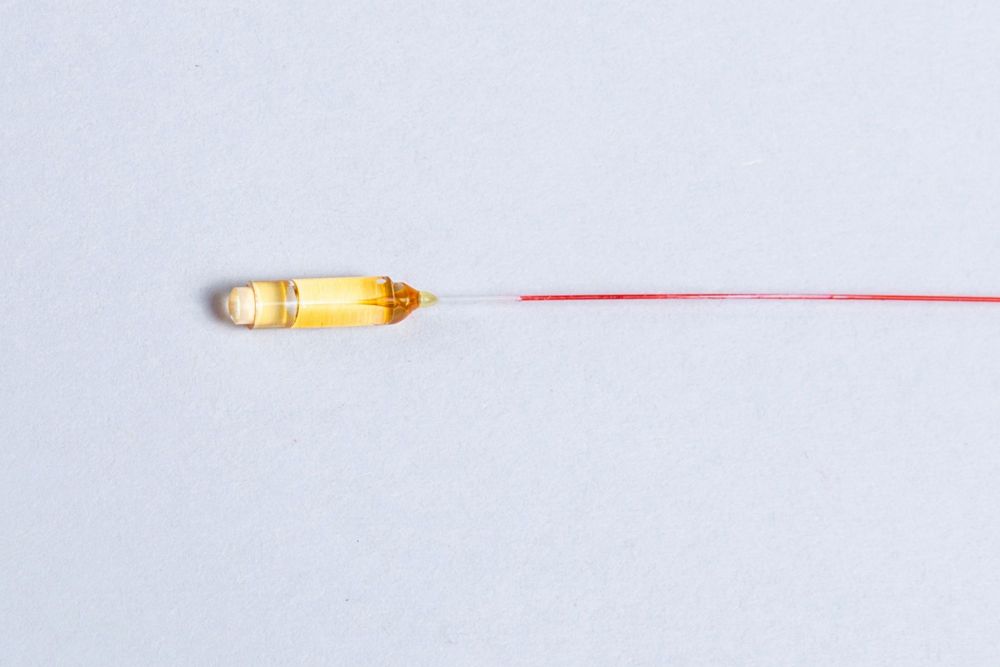

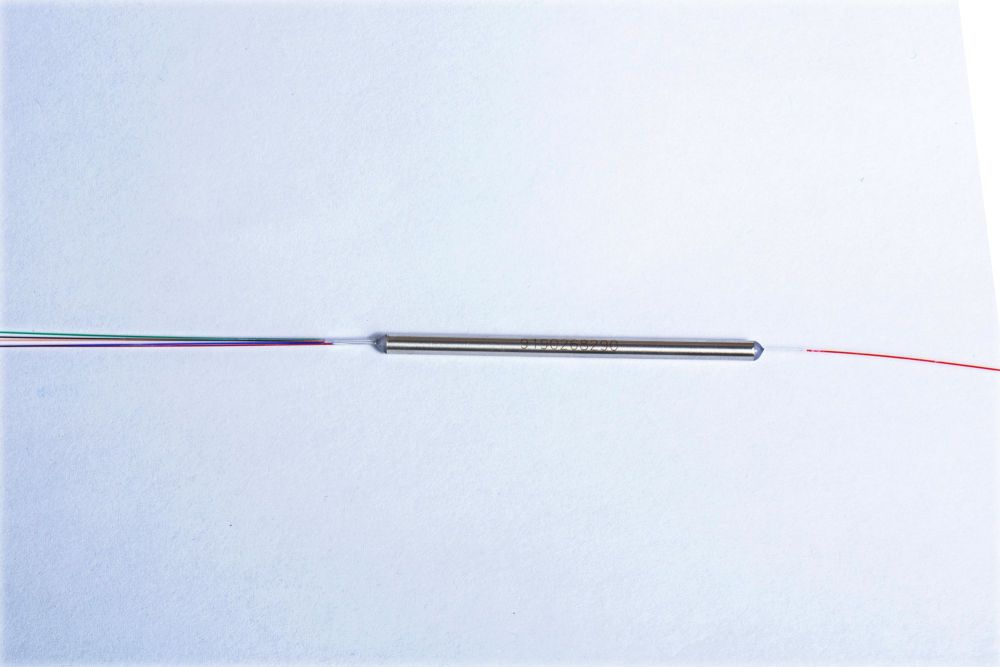

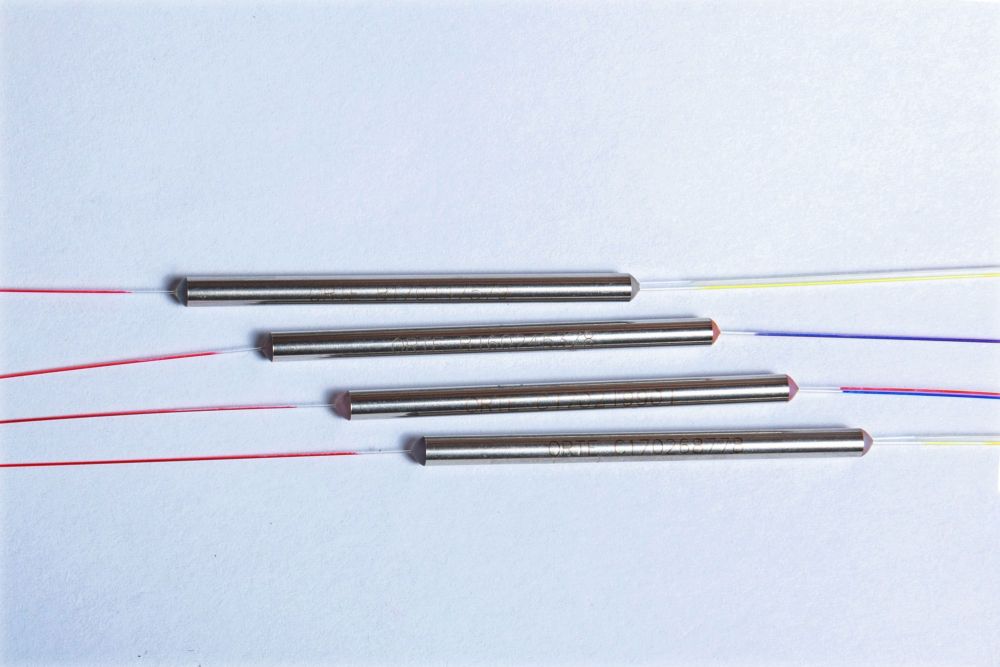

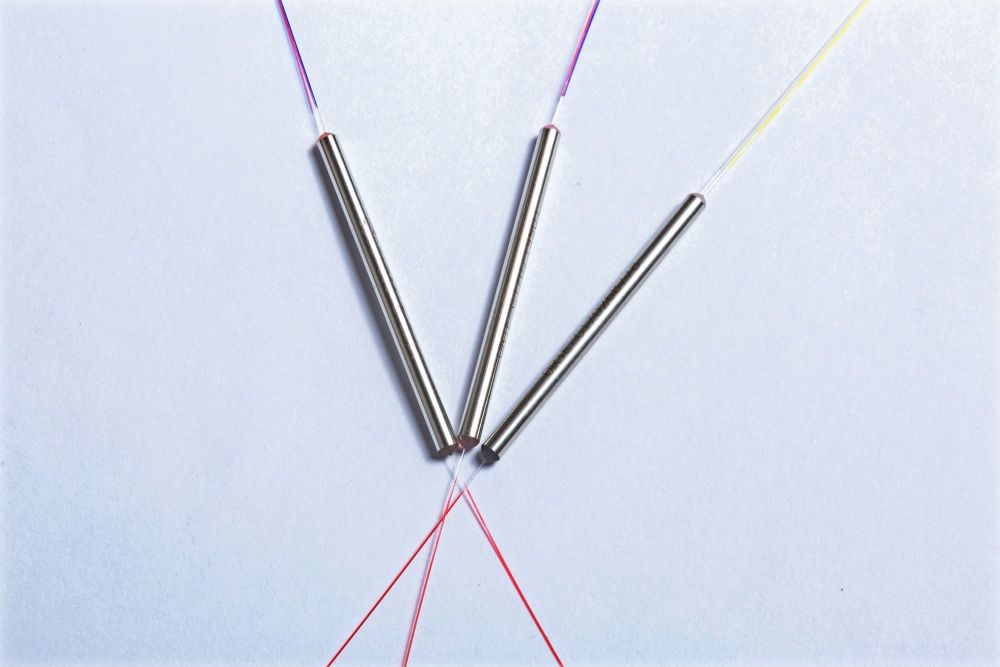

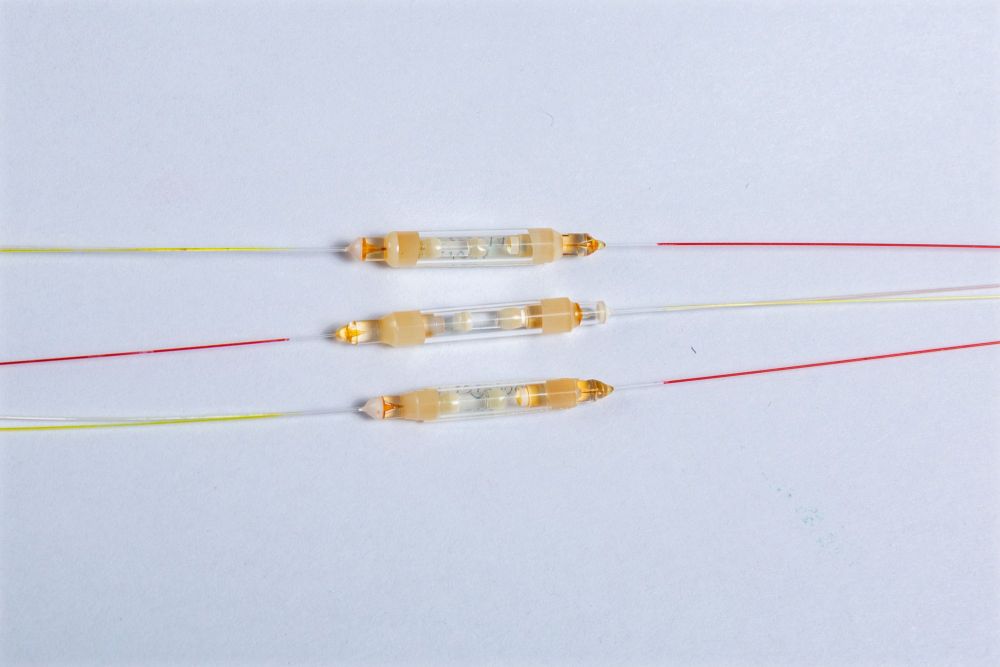

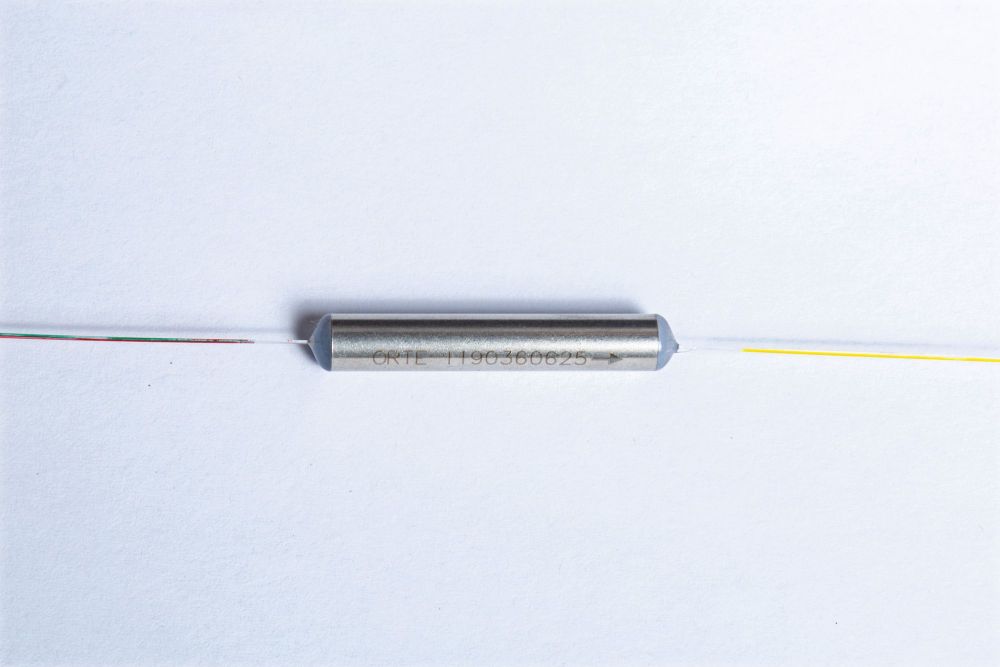

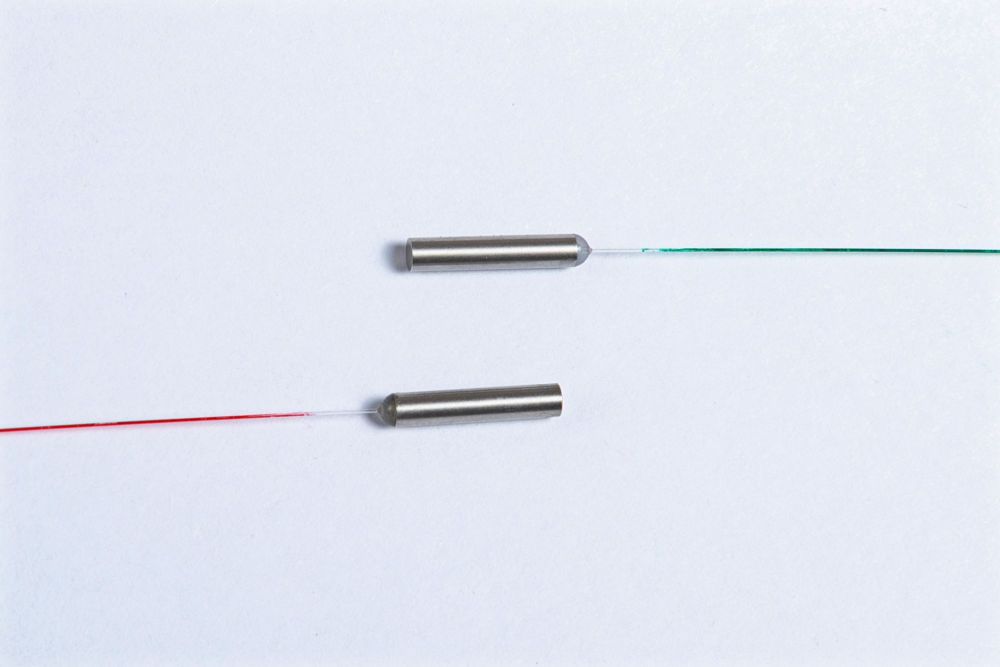

To screen out stress-damaged devices, we designed a 100% screening test. The purpose of the screening test is to remove the points where the strength of the entire fiber processing length is lower than or equal to the screening stress, so as to ensure the mechanical reliability of the surviving fiber. Here the picture is how the test works. Our customers are all pleased with what we have done the our products.