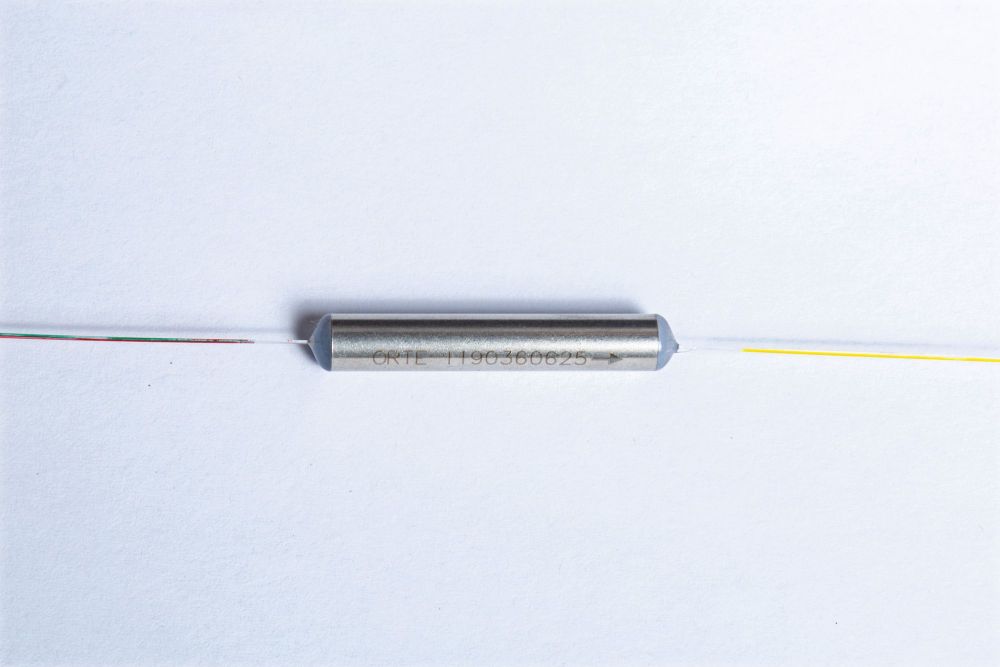

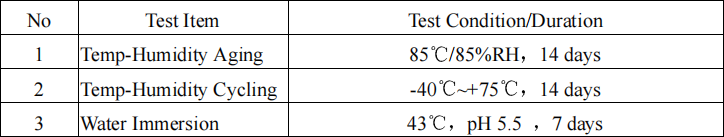

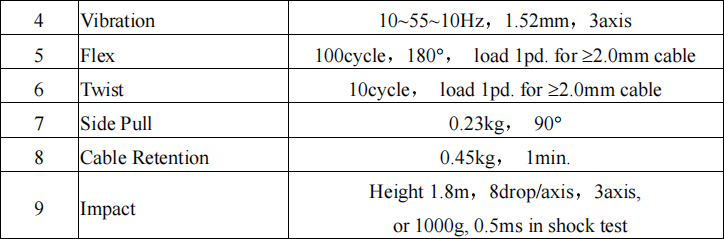

In commercial applications, the miniaturization of optical passive devices has become a trend in commercial and product promotion. It is difficult to use complex protective mechanisms to improve the reliability of fiber optic couplers. Therefore, the reliability requirements should be taken into account in the design stage (design-in) to ensure that the product can meet or exceed the requirements of the reliability test and failure mode Analysis (FMEA) Establishing effective control and inspection methods during mass production, continuous analysis and improvement of abnormal conditions, and screening with appropriate environmental stress when necessary, can improve the reliability of optical passive devices. In this situation, standard of GR-1209 is the regulation of commercial fiber optic couplers. The reliability test items include environmental tests and mechanical tests. The test items and conditions are shown in below table.

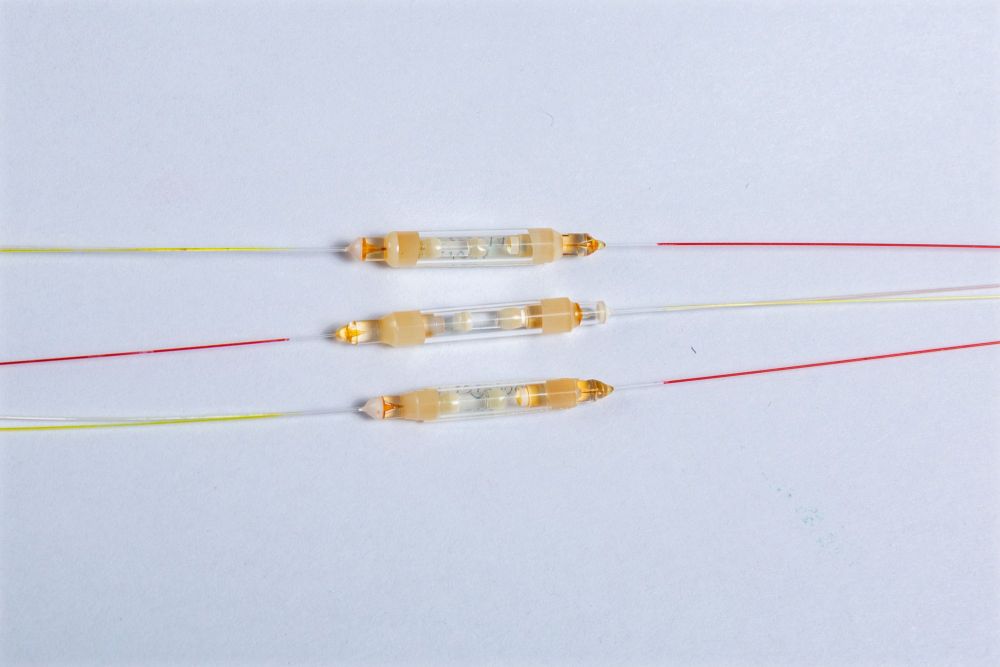

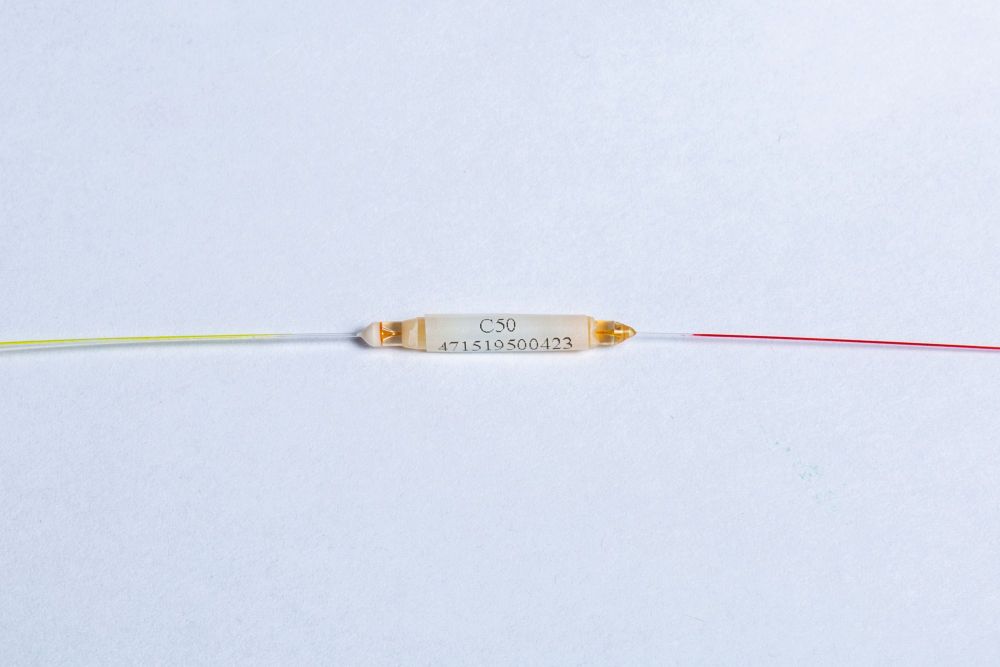

Environmental Testing In the environment where the optical splitter is used, the thermal expansion and contraction of the optical fiber will inevitably be caused by the change of ambient temperature and humidity, which will affect the optical characteristics, especially the insertion loss (Insertion Loss) and the polarization dependent loss (PDL Polarization). Dependent Loss), so the substrate selected for the packaging process and the glue used to fix the optical fiber and the substrate must be considered to be equivalent to the thermal expansion coefficient of the optical fiber to avoid the optical characteristics being changed sharply due to environmental changes. In addition, due to the characteristics of the glue It is easily affected by moisture in the air. Therefore, it is necessary to use sealant glue in the packaging design of the optical splitter to prevent external moisture from affecting the characteristics of the substrate glue and negatively affecting the optical characteristics. In environmental tests such as Temp- The main purpose of reliability tests such as Humidity Aging Temp-Humidity Cycling is to verify whether the glue used to fix the optical fiber on the optical splitter substrate and the glue used for the package can guarantee the optical splitting under the specified time and conditions in terms of design and material selection. The optical characteristics of the device can still meet the requirements.

Temp-Humidity Aging Test

1. Adhesion of sealant glue to optical fiber steel pipe and the characteristics of high temperature and high humidity resistance

2. The effect of temperature and humidity on sealant glue

3. Design of sealing structure to prevent moisture penetration

4. Adhesion of the glue for fixing the optical fiber at both ends of the substrate to the optical fiber substrate and the characteristics of high temperature and high humidity resistance

Temp-Humidity Cycling Test

1. Matching of thermal expansion coefficients of different materials

2. Factors such as the stability of the adhesive force of the glue fixing the optical fiber at both ends of the substrate relative to the temperature change and the Tg value

3. The position of the glue between the optical fiber and the substrate

4. Design of packaging structure and response to temperature changes

Water Immersion test

1. Adhesion and waterproofness of sealant glue to optical fiber and steel pipe

2. Sealed structure to prevent water penetration

3. Absorption of water vapor by sealant glue